Nanoparticles – When Smaller is Better

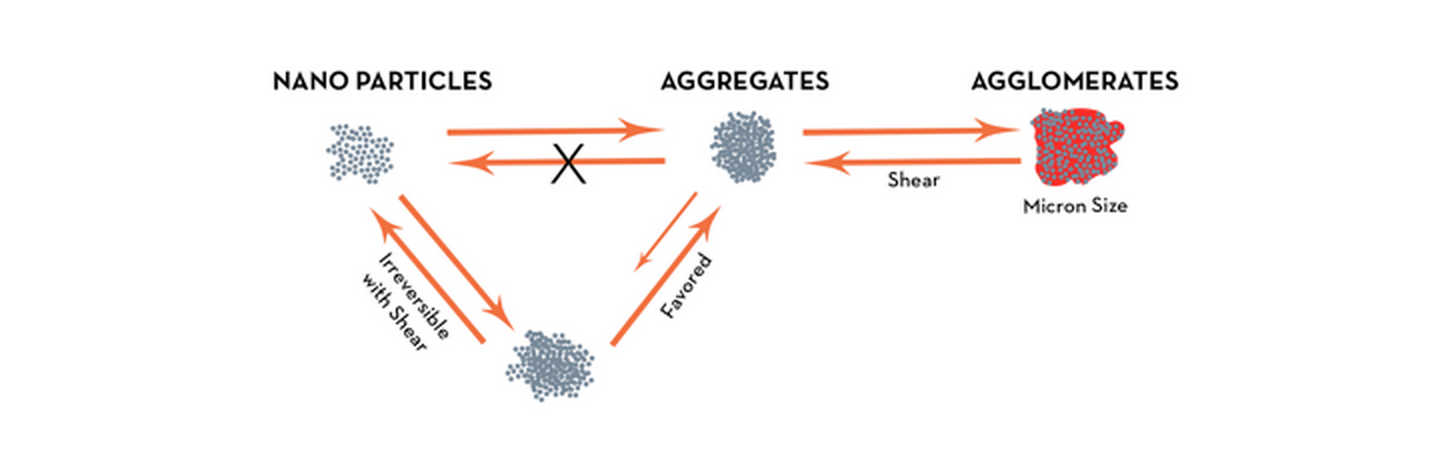

Nanoparticles (EU) are normally defined as those particles that have a dimension of between 1 and 100 nm. The use of nanoparticles in coatings has provided a means to further improve performance such as scratch resistance, hardness, antistatic properties and UV resistance. These performance attributes are derived from the property profiles of nanoparticles.

Nanoparticles provide the inherent properties of the material they are derived from. For example, nano alumina (EU)maintains the properties of alumina, such as hardness and scratch resistance, but only on a nanoscale. Likewise, nano silica(EU) provides hardness, nano titanium dioxide provides a high refractive index and UV stabilization, and nano zinc oxide(EU) remains a UV light absorber (EU), even if the zinc oxide particles are nano-sized. The benefits of these materials are imparted to the coatings that they are used in.

The most pronounced property that is influenced by the particle size is the change in light scattering. For example, nano-sized particles may produce transparent coatings as light-scattering decreases with decreasing particle size. Most objects are visible due to light scattering from their surfaces. Scattering of light depends on the wavelength or frequency of the light being scattered as well as the size, shape and type of particle.

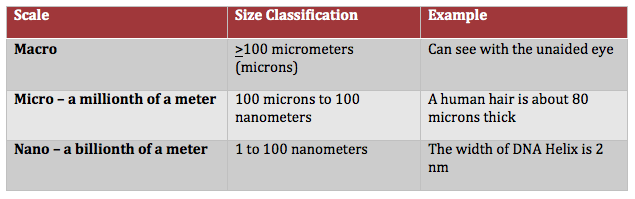

Table I – Particle Size Perspective

To read the full article written by Ron Lewarchik, Chemical Dynamics President, on UL Prospector, click here.

New US Patent on Rust Coatings Granted

US Patent on Coatings that Arrest Rust Granted to Chemical Dynamics LLC

US Patent 8,927,649 was awarded to Chemical Dynamics LLC on January 6, 2015. US Patent 8,927,649 covers of a film forming penetrant coating with a high cross-link density that arrests corrosion on rusty substrates.

Patent Abstract: A one part, storage stable polymerizable formulation is provided that includes an ethenically unsaturated polymerizable compound intermixed with a free radical polymerization initiator and an organic solvent. The organic solvent provides storage stability and upon evaporation of the solvent, the rate of polymerization of the compound accelerates independent of addition of a second part. The formulation includes at least 30 total weight percent solids upon cure. Optional additives to the formulation include at least one of a cure accelerator, a filler, a plasticizer, a colorant, and a cure inhibitor. A process for forming a polymerized coating on an article involves the application of this formulation to the substrate of an article and allowing sufficient time for the solvent to evaporate to form the polymerized coating on the article. The substrate of the article forms a corrosion barrier even without prior removal of a native corrosion layer on a surface of the substrate of the article.