Atman Fozdar1, Ronald Lewarchik1 ‘, Raviteja Kommineni1, Vijay Mannari2 ; Chemical Dynamics LLC1, Michigan, USA; Eastern Michigan University2, Michigan, USA

Abstract

With the recent advances in the formulation of powder coatings, it’s quite possible to formulate powder coatings that apply to temperature sensitive surfaces and cure at low temperatures using IR or UV cure. However, the challenge still remains with the electrostatic application of powder and liquid coatings that enable acceptable adhesion to non-traditional substrates (porous substrates like MDF, particle board, trim board and non-porous substrates like wood plastic composites, plastics composites, glass, ceramic etc.) and achieve good transfer efficiency. Insufficient and/or non-uniform surface treatment of these substrates prior to application results in a non-uniform finish, multiple film defects and poor transfer efficiency.

Our research has led to the development of rapid drying conductive adhesion promoters (CAP’s) with improved adhesion of powder and liquid coatings to nonconductive substrates such as MDF, particle board, trim board, wood plastic composites, fiber reinforced composites, ABS, Polycarbonate, Noryl GTXTM, SMC and Polyolefinics etc.; while at the same time improving transfer efficiency by dissipating static charge. The ability of our CAP technology to dry quickly permits application in a continuous/conveyorized production line followed by the application and curing of powder and liquid coatings. The use of CAP’s in this process eliminates the need for preheating, plasma treatment and chemical etching of plastic substrates while improving both film appearance and application efficiency. UV curable as well as LTC (low temperature cure) powder and liquid coatings can now be applied uniformly even in recess areas/faraday cage areas. This patent pending technology utilizes novel conductive materials in conjunction with a polymeric adhesion promoter and at the same time improves flexibility and interfacial adhesion along with anti-static properties.

Conventional treatments used to enhance surface conductivity utilize quaternary ammonium salts dispersions (QAS) which render the coated substrate conductive, but moisture sensitive as the QAS conductive treatment are water sensitive and migratory. Lastly, QAS technology does not enhance adhesion and flexibility.

Introduction

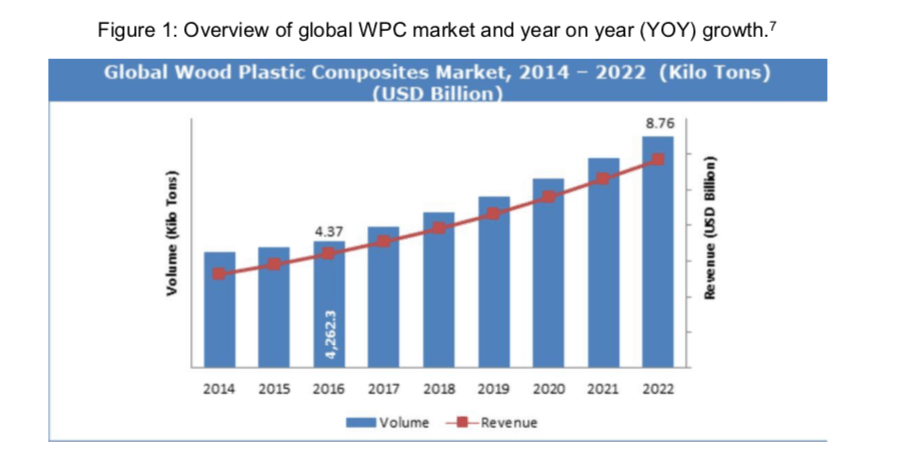

With recent modifications in polymer composition, WPCs are not only used in construction industry for outdoor decking but also automotive, furniture, fencing, landscape timber, playground equipment etc. There are several advantages of using WPCs such as,

- Use of recycled materials

- Lower maintenance than their wood counterparts

- Higher thermal stability than plastic composites

- Higher dimensional stability than wood

- Lower moisture absorption

- Better machinability etc.

One of the issues, faced by most WPC manufacturers and consumers is, “paintability” of a coating over WPC. Due to lower surface energy of polypropylene and/or PVC or most plastics used, most conventional coatings don’t have good adhesion to WPCs, and can result in delamination after a short period when subjected to extreme heat/cold cycles.

In this scope of work, powder coating was identified as most suitable and eco-friendly coating for WPC due to several reasons such as:

- No VOCs

- Higher transfer efficiency (up to 90-95%),

- Overspray can be reused

- Superior film properties (Tough, durable, hard, scratch resistant)

- Reduced process time and energy requirements

- One step finishing process.

However, there are certain challenges to powder coat plastics and composites. Such as,

- Application of powder coating using electrostatic spray on non-conductive WPC, MDF, particle board and plastic composites

- Adhesion of powder coating on WPC with low surface energy

- Selecting the right chemistry of powder which cures at low temperature due to low heat deflection temperature of powder coatings.

Application of powder coatings on MDF is also covered within this scope of research, since there are multiple issues related to appearance and film formation when powder coating MDF using conventional approaches such as preheating MDF to,

- Fatty edges,

- Edge cracking,

- Pin holes,

- Non-uniform appearance and film thickness,

- Ability to coat recess areas/areas not in direct line of sight

Methodology to overcome above challenges is described below.

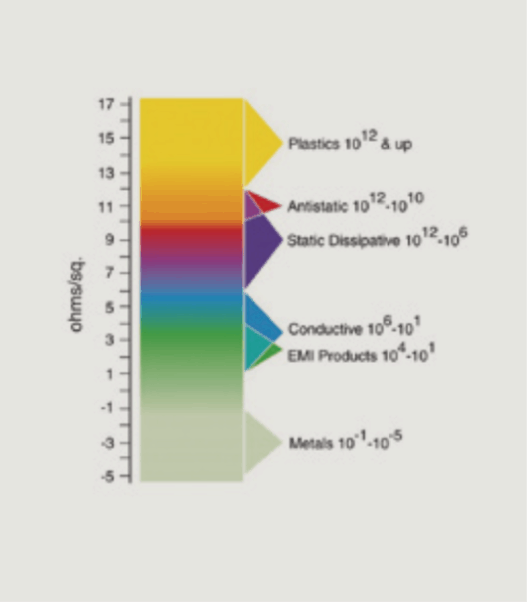

Surface Resistivity

Quantification of the classification of surface resistivity:

Anti-static

- Decay rate (seconds to decay), 5000 to 50 V at 12% Relative humidity

- Standard : MIL PRF 8705 D, NFPA 56A Static dissipative (ESD)

Static dissipative (ESD)

- Surface resistivity (ohm/square)

- Surface resistance (Ohm)

- Standard : ASTM D257, ESD STM11.11, IEC 60079-0 Conductive

Conductive

- Volume resistivity (Ohm-cm)

- Surface resistivity (Ohm/square)

- Standard : ASTM D257 EMI/RFI shielding

EMI/RFI shielding

- Shielding effectiveness (decibels of attenuation)

- Standard : ASTM D4935

- For a successful application of powder coatings (uniform appearance, film formation and deposition of powder particles on substrate as well as in recess areas where there is no direct line of sight at the time of application) on WPC and plastic substrates, surface resistivity of substrate is required to be less than 108

Ohm/Square (from our previous work published in European Coatings Journal, 20171). Thereby, placing it in conductive, static dissipative range as per Figure 2.

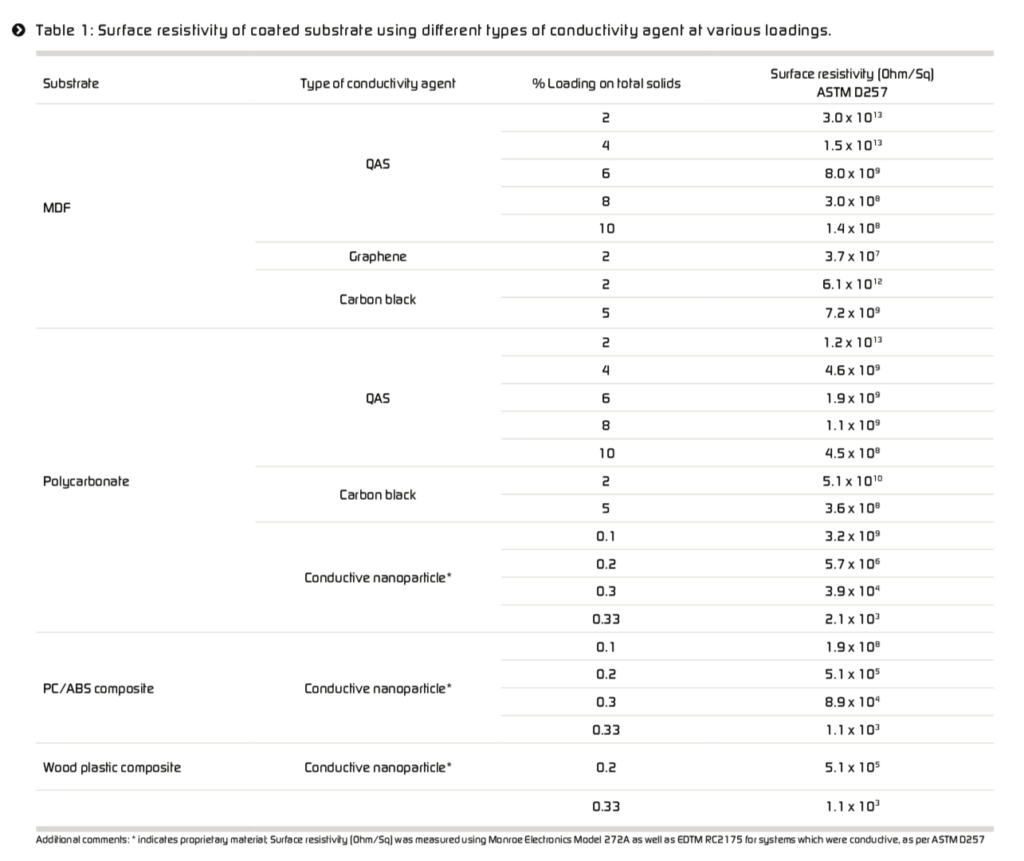

In our scope of research, we evaluated different types of conductivity agents such as quaternary ammonium compounds (QAS), carbon black, graphene as well as conductive nano particles (functionalized and/or non- functionalized).

To determine most suitable conductivity agent, we formulated a DOE and coated different porous and non- porous non-conductive substrates with different conductivity agents at various loading. Surface resistivity of which is listed in Table 1.

Additional comments: * indicates proprietary material; Surface resistivity (Ohm/Sq) was measured using Monroe Electronics Model 272A as well as EDTM RC2175 for systems which were conductive, as per ASTM D257.

Surface resistivity results listed in the above Table 1 show very little or no discrepancy since results of each variation on all of the substrates are very close to each other.

Apart from conductivity imparted, there are several disadvantages of using QAS, since they are humidity, process and temperature dependent. Their migratory nature doesn’t ensure sufficient adhesion of top coat to substrate or flexibility.

For conductive carbon black, significantly high loading is required to get low enough surface resistivity so that uniform film formation of powder coating can be achieved. High loading of conductive carbon black pigment can also lead to “crayoning” effect and adversely affect mechanical properties.

Results enlisted in Table 1 also confirm that if we increase the conductive agent loading beyond certain point then decrease in surface resistivity doesn’t necessarily need to be substantial or linear. Hence, there is a need to find the optimum amount for each type of substrate i.e. porous (such as MDF) and non-porous (polycarbonate, PC/ABS, glass and wood plastic composite which is less porous comparatively).

Adhesion of powder coatings on plastics:

A major issue which confronts coatings and ink industry is the adhesion of liquid and powder coatings to WPC and plastic composites. There are several conventional approaches such as flame treatment, corona discharge, gas plasma, UV exposure or chemical oxidation which may be used to oxidize the surface of the substrate to promote adhesion. Oxidizing the surface would increase polar contribution to surface energy and produce more polar sites for bonding without altering the dispersive contribution significantly. The coating is best applied soon after treatment because the oxidation produces short lived radical species and is partially reversible with time. A major difficulty with ‘radiative’ techniques is achieving uniform surface coverage without over-treating, which introduces chain-scission and can lead to cohesive failure within surface of the substrate.

Mechanism of crosslinking involves several different reactions of acid functional groups forming N-acylurea, aminoester and reaction with epoxide functionality as well as hydrolysis of alkoxysilane.

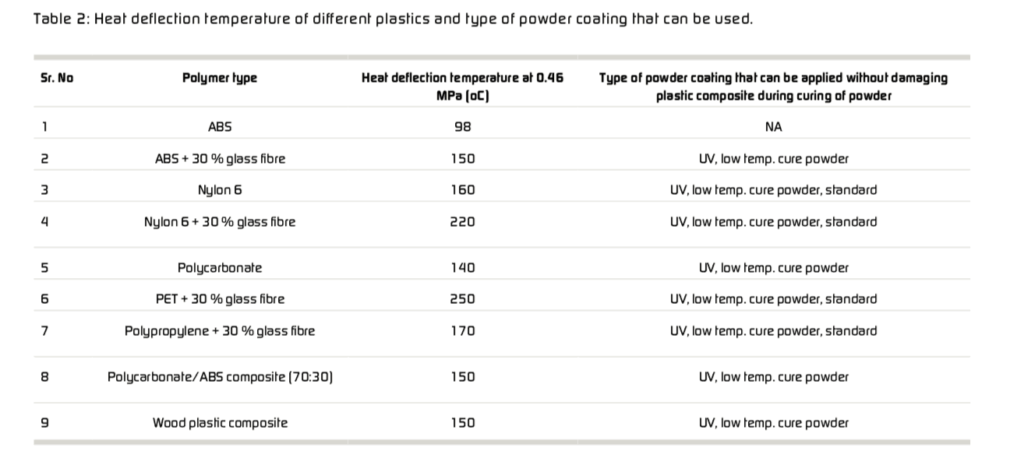

Selection of powder coating based on type of substrate

Not all WPCs and plastic substrates can withstand high curing temperature of 160-200 C of conventional powder coating. Most plastics tend to soften, degrade or even melt at such high temperature. It’d be safe to apply and cure powder coating below substrate’s heat deflection temperature.

Heat deflection temperature is a measure of polymer’s ability to bear a given load at elevated temperatures.

Application of CAP and powder coating

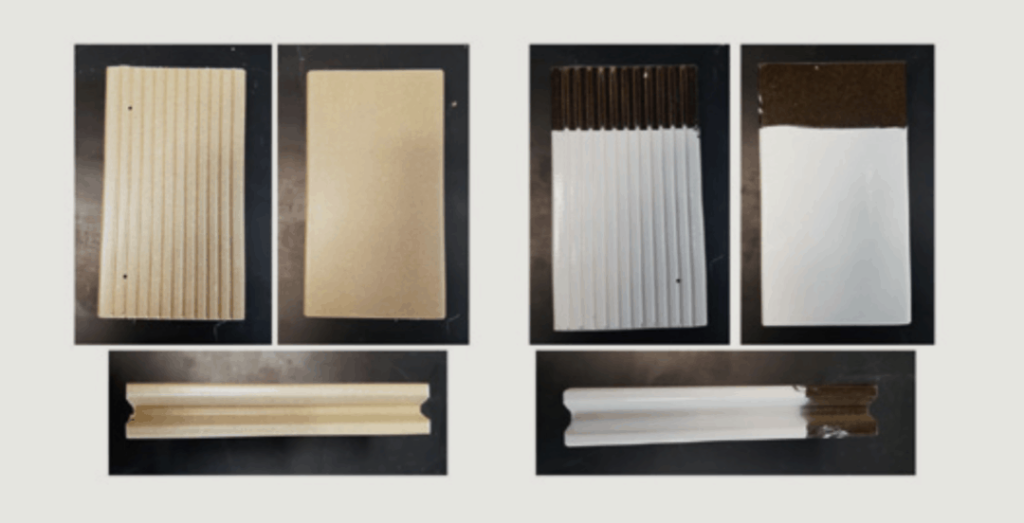

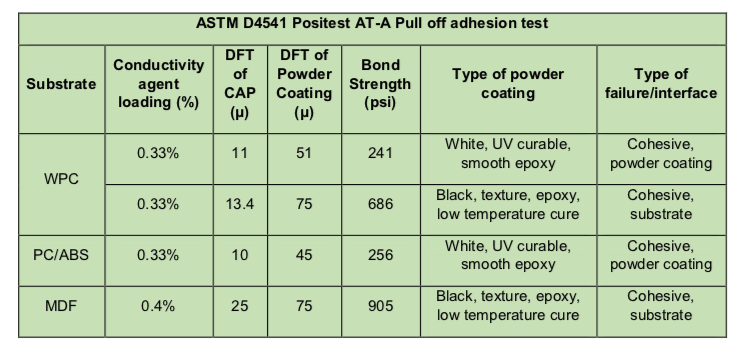

CAPs were applied on wood-plastic composite, PC/ABS and MDF at 10-14 microns dry film thickness using HVLP spay gun at 20 psi air pressure at nozzle. They were dried/cured at ambient temperature for 8-10 minutes.

UV curable smooth, white epoxy powder coating and low temperature cure black, texture epoxy powder coating was applied using electrostatic spray gun on substrates coated with CAP.

Melting and curing schedule of UV curable powder coating:

UV curable powder was melted first at 120o C for 3-4 minutes and then cured using conveyorized UV oven having medium pressure H-bulb. Low temperature black, texture epoxy powder coating was cured at 130o C for 8 minutes

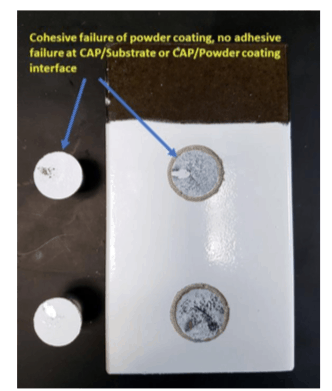

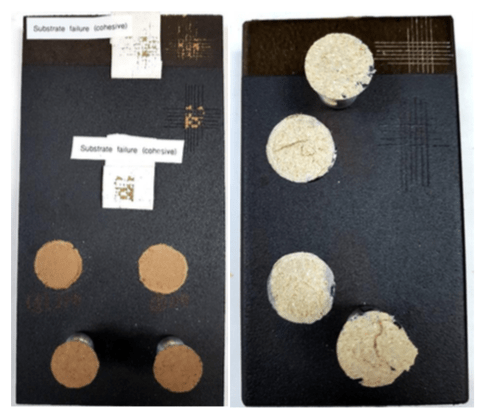

Additionally, Positest pull off adhesion test was carried out to determine interfacial adhesion. Multiple adhesion tests with 20 mm dollies were carried out to determine interface of the coating failure and the force/area at which failure happens.

Dry film thickness of CAP and cured powder coating was measured using Positector B100/B200, ultrasonic film thickness gauge.

Conclusion

- CAPs ensure sufficient dissipation of negatively charged powder particles applied by electrostatic spray equipment as well as promote interfacial adhesion.

- CAPs work more efficiently at lower film thickness on non-porous substrates. On porous substrates higher film thickness is required since some of the material is absorbed by porous substrate.

- CAPs form chemical and mechanical bonds with porous substrates which result in high pull-off bond strength compared to non-porous substrates like PC/ABS composite.

- CAPs enable successful application of powder coating on various WPCs, plastic composites, MDF, trim boards, concrete and ceramic tiles, porcelain (uniformity, film formation, ability to coat recess areas etc) with no film defects such as fatty edges pin holes, blisters, edge cracks etc.

- CAPs can significantly increase transfer efficiency of applying liquid or powder coating to plastic composites having complex geometry.

Future Directions

- Reduce dry film thickness (DFT) for thinner film applications (3-6 microns).

- Increase crosslink density by changing composition of reactive species.

- Reduce dry to touch time to 3-4 minutes from 8 minutes.

- Accelerated weathering of coated WPC and MDF materials along with thermocycle resistance (cyclic exposure to extreme heat and cold).

References

- Fozdar A., Mannari V. “Development of Low VOC Static Dissipative Coating for Powder Coating Non-Traditional Substrates.” European Coatings Journal, April 2017.

- Carlos L., Almeida P. ‘Conducting Polymers : Synthesis, properties and applications (polymer science and technology)’.

- Cudazzo M/, R. Knofe. “Powder Coating of Substrates with Low Electrical Conductivity: A New Powder Coating Process for Non-Metallic Workpieces and Components,” January 1998.

- Gao S., Zhu X.P, and Jesse (Jingxu) Zhu. “Powder Coating of Plastic Components,” September 2016.

- Schwarb R., Knoblauch M. “UV-Curable Powder Coatings for Heat Sensitive Substrates.” CoatingsTech, July 2010.

- Zeren S, Huguenard S. “UV Curable Powder Coatings: Formulation of Thick White Finish for MDF.” Surface Coatings International Part B: Coatings Transactions 87, no. 2 (June 2004).

- “Global Wood Plastic Composite Market” Zion market research, 2017.