ORIGINALLY PUBLISHED IN EUROPEAN COATINGS JOURNAL 11 – 2018

Enhanced technology for electrostatic spray on nonconductive substrates and complex geometries. By Atman Fozdar, Ronald Lewarchik, Chemical Dynamics LLC, USA, and Vijay Mannari, Eastern Michigan University, USA.

Light vehicles represent an important market for plastics and poly- mer composites, one that has grown significantly in the last five decades. Among other reasons, this is due to being inexpensive com- pared to their metal counterparts, to being able to mould complex geometry, to reduced weight, and to increased fuel economy due to the reduced weight. Various plastics and composites are used for automotive interiors, exteriors, electrical systems, powertrains and engine components. Their complex geometries and the non-conductive nature of the substrate mean that coatings cannot be applied using electrostatic spraying, which limits the methods for applying coatings by the conventional spraying method. A conventional liquid coating spray method causes significant loss in transfer efficiency (about 40- 60% depending on geometry of the substrate), so there is an obvious market opportunity here.

Powder coatings have been identified as the most suitable and eco-friendly coatings for plastics because, for instance:

- No hazardous Volatile Organic Compounds (VOCs)

- Higher first-pass transfer efficiency (up to 90-95 %),

- Overspray can be reused/reclaimed.

- Superior film properties (tough, durable, hard, scratch resistant)

- Lower process time and energy requirements.

- One-step finishing process.

- However, powder coating plastics and composites gives rise to certain challenges, such as:

- Applying a powder coating using electrostatic spray on non-con-

ductive plastics and composites.

ą Adhering a powder coating on plastics with low surface energy.

ą Selecting the right powder chemistry that cures at low temperature

due to low heat-deflection temperature of plastics and composites.

We have developed a method that overcomes these challenges.

Use of CAPs eliminates the need for preheating, plasma treatment

and chemical etching of plastic substrates while improving both film

appearance and application efficiency.

Results At A Glance

- A new conductive adhesion promoter (CAP) technology for application in a continuous/conveyorised production line, dries quickly.

- UV curable as well as low temperature cure (LTC) powder and liquid coatings can now be applied uniformly even in re- cess/Faraday cage areas on plastic composites.

- CAPs work more efficiently at lower film thickness on non- porous substrates.

- CAPs can significantly increase the transfer efficiency of applying a liquid or powder coating to plastic composites with complex geometry.

Surface Resistivity is Key

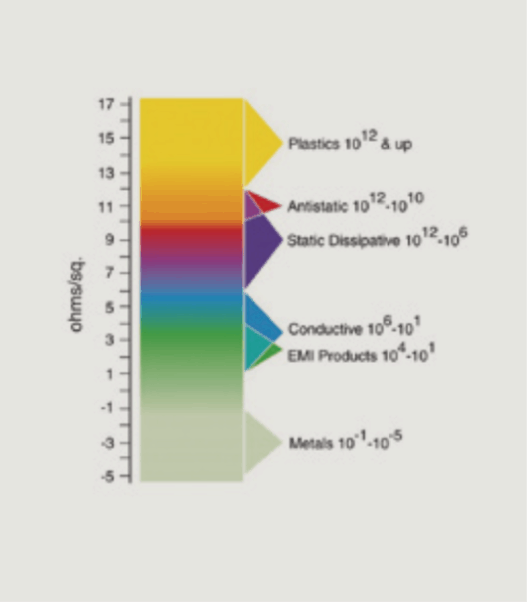

Figure 1 classifies conductive materials by surface resistivity. For successful application of powder coatings on plastic substrates, surface resistivity of the substrate has to be less than 108 Ohm/Square (from our previous work published in European Coatings Journal, 20171). This places it in the conductive, static dissipative range as per Figure 1. (We define a successful application as uniform appearance, film formation and deposition of powder particles on substrate as well as in recess areas where there is no direct line of sight at the time of application.)

Quantification of classification of surface resistivity:

Anti-static

Decay rate (seconds to decay), 5000 to 50 V at 12 % relative humidity

Standard : MIL PRF 8705 D, NFPA 56A

Static dissipative (ESD)

Surface resistivity (ohm/square)

Surface resistance (Ohm)

Standard : ASTM D257, ESD STM11.11, IEC 60079-0

Conductive

Volume resistivity (Ohm-cm)

Surface resistivity (Ohm/square)

Standard : ASTM D257

EMI/RFI shielding

Shielding effectiveness (decibels of attenuation)

Standard : ASTM D4935

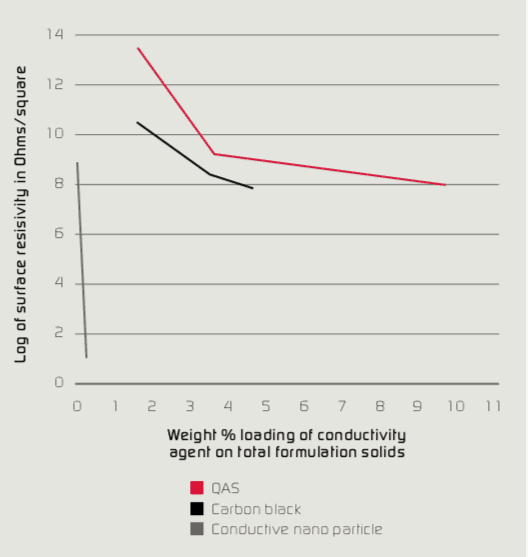

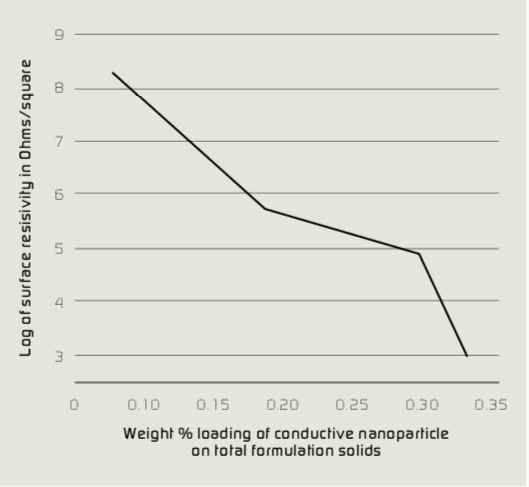

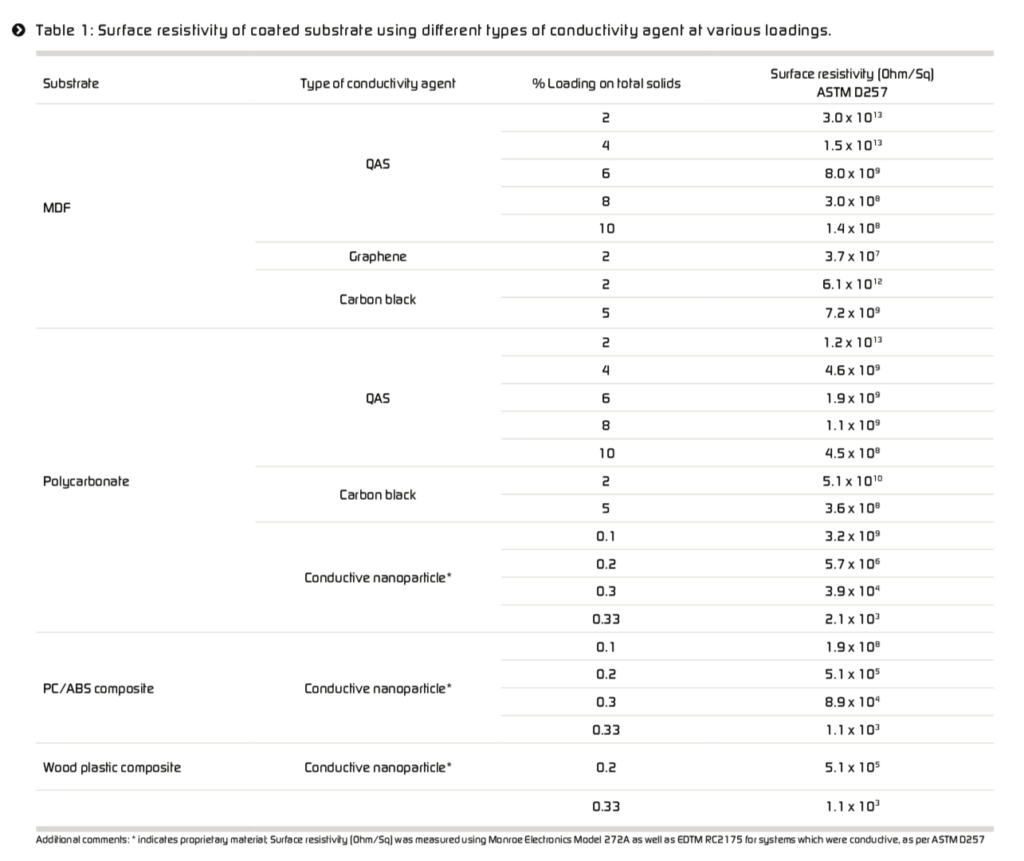

We evaluated different types of conductivity agents such as quater- nary ammonium compounds (QAS), carbon black, graphene and also conductive nanoparticles. To determine the most suitable conductiv- ity agent, we formulated a design of experiments and coated various porous and non-porous, non-conductive substrates with different conductivity agents at various loadings. Their surface resistivities are given in Table 1 & Figure 5 & 6. These results show very little or no discrepancy since the variations on all of the substrates are very small.

Apart from conductivity imparted, using QAS has several disadvantag- es, since they are humidity-, process- and temperature-dependent. Their migratory nature does not ensure sufficient flexibility or adhe- sion of top coat to substrate. For conductive carbon black, significantly high loading is required to get low enough surface resistivity so that the powder coating forms a uniform film, and they deteriorate me- chanical properties of the film.

Table 1 also shows that if we load the conductive agent beyond a certain point then the decrease in surface resistivity is not necessarily substantial or linear. We need to find the optimum amount for porous substrates (such as MDF) and non-porous substrates (e.g. poly- carbonate, PC/ABS, glass and wood-plastic composite, which is less porous comparatively).

Adhering Coatings on Plastics

The coatings and ink industry faces the challenge of the adhesion of liquid and powder coatings to plastics, especially thermoplastic olefins. Conventional approaches such as flame treatment, corona discharge, gas plasma, UV exposure and chemical oxidation can be used to oxidise the surface of the substrate to promote adhesion. Oxidising the surface increases polar contributions to surface energy and produces more polar sites for bonding without altering the dispersive contribution significantly. The coating is best applied soon after treatment because the oxidation produces short-lived free radical species and is partially reversible. A major difficulty with ‘radiative’ techniques is achieving uniform surface coverage without over-treating, which introduces chain-scission and can lead to cohesive failure within the surface of the substrate.

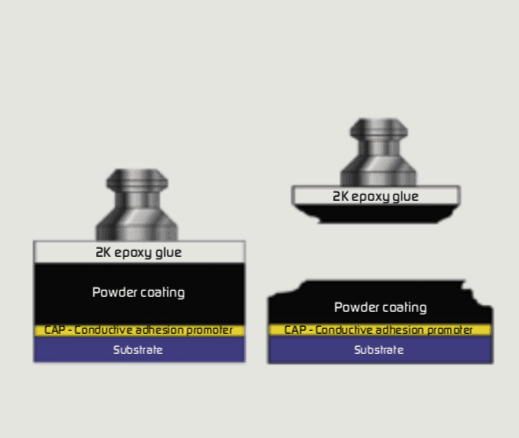

The amount of halogen in the modified polymeric adhesion promo- tor determines the compatibility with various paint systems. Once the polymeric adhesion promoter is dispersed with conductive nanoparticles, it associates with plastics and composite substrates via dispersion interaction and adheres to it. Halogenated material and grafted functional groups add polarity to CAP which promotes interfacial adhesion to the substrate and the powder/liquid top coat.

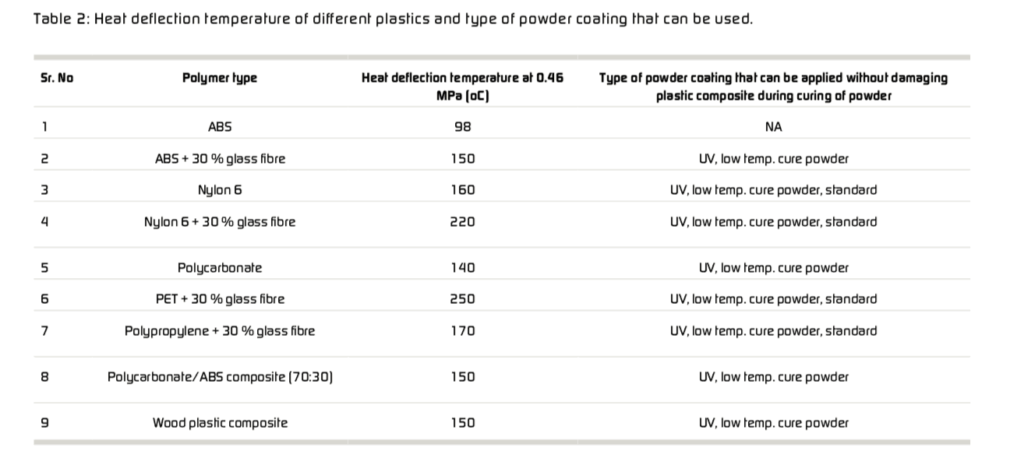

Type of Substrate Matters Greatly

Not all plastic substrates can withstand the high curing temperatures of conventional powder coating, 160-200 °C. Most plastics tend to soften, degrade or even melt at such high temperatures. It is safe to apply and cure powder coatings below a substrate’s heat deflection temperature. The heat deflection temperature is a measure of poly- mer’s ability to bear a given load at elevated temperatures.

Method

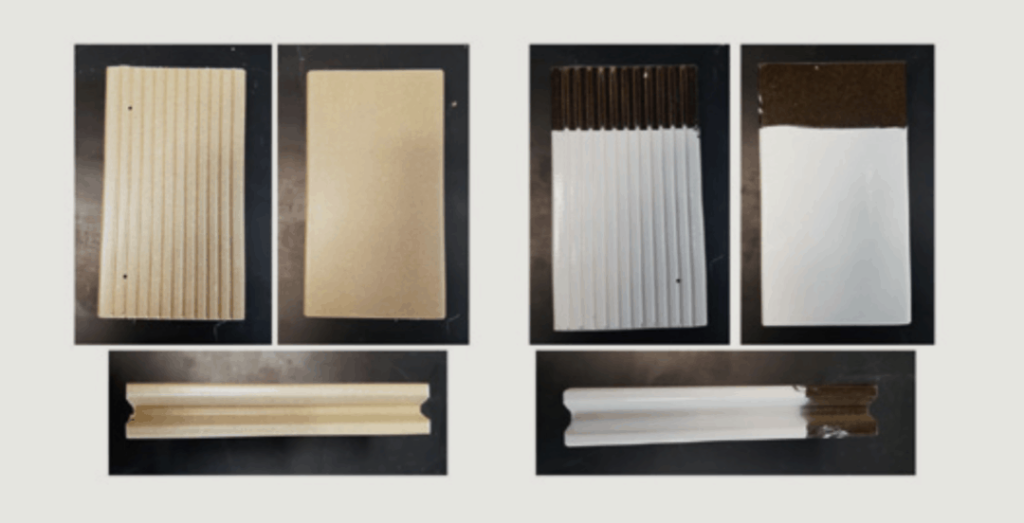

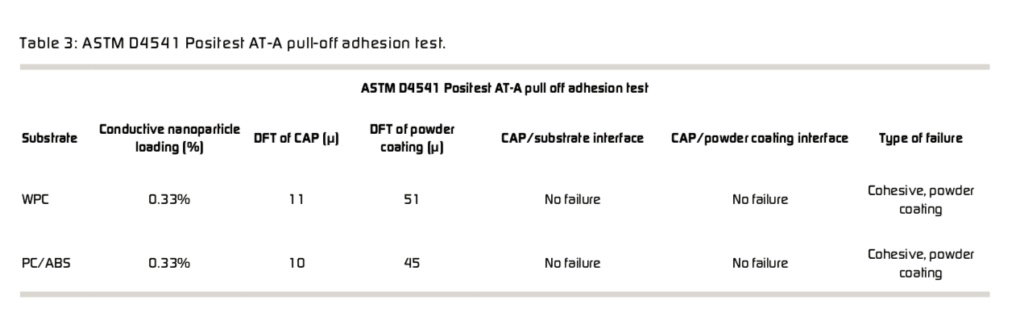

CAPs were applied on a PC/ABS and MDF, wood-plastic composite curved porcelain tile at 10-14 μm dry film thickness using an HVLP spray gun at 20 psi air pressure at the nozzle. They were dried/cured at ambient temperature for 3-5 minutes.

A UV curable smooth, white, epoxy powder coating (Figure 2 & 3) and low temperature cure textured black hybrid (epoxy/polyester) powder coating (Figure 7) were applied using an electrostatic spray gun on substrates coated with CAP. The UV curable powder was melted first at 120 °C for 3-4 minutes and then cured using a conveyorized UV oven with a medium-pressure H-bulb, and low temperature cure powder was cured at 130 °C for 5 minutes.

Positest pull-off adhesion tests were carried out to determine interfacial adhesion. Multiple adhesion tests with 20 mm dollies were carried out to determine the interface of the coating failure and the force/ area at which failure happens. The dry film thickness of the CAP and the cured powder coating were measured using Positector B100/ B200, an ultrasonic film thickness gauge (Table 3, Figure 4 & 8).

Where Are We Now?

- CAPs ensure sufficient dissipation of negatively charged powder particles applied by electrostatic spray equipment and promote interfacial adhesion.

- CAPs work more efficiently at lower film thickness on non-porous substrates. On porous substrates higher film thickness may be required since some of the material would be absorbed by a porous substrate.

- CAPs enable successful application of powder coating on various plastic composites (uniformity, film formation, ability to coat recess areas, etc.).

- CAPs can significantly increase transfer efficiency of applying liquid or powder coating to plastic composites having complex geometry.

3 questions to Atman Fozdar

How do you define “traditional“ and “non-traditional“ substrates?

Current electrostatic application technology only allows metallic substrates (which are inherently conductive and need to be grounded to dissipate static charge) to be successfully powder coated. Conductive Adhesion Promoter (CAP) technology enables successful application of powder coatings on non-conductive or non-traditional substrates like glass, ceramic, plastics, composites, wood, WPC etc. by making the surface of the substrate conductive and by improving interfacial adhesion between powder coating and the substrate, which was not possible otherwise with conventional Quaternary Ammonium Salts and other approaches.

What other plastic coating applications are feasible besides light vehicles applications?

Plastic composites used in automotive is just one of the examples to demonstrate CAP technology. Practically, any plastic substrate or composite (used in appliance, construction, medical or industrial areas) that can withstand 120 °C (melting temperature of powder) can be powder coated. We an- ticipate a huge potential for the wood-plastic composite market as well as recycled plastics for more efficient coating application with higher first-pass transfer efficiency and zero VOC.

What are the most important challenges that must be overcome before commercialisation of this technology?

We’re working on optimising formulations for porous substrates like MDF. In addition to that, a zero VOC water-borne version of CAP takes about 8-10 minutes to dry/cure. We’re evaluating other polymers to reduce dry/cure time so that it can be used in continuous/conveyorised environment for increased productivity.

References

[1] Fozdar A., Mannari V. “Development of Low VOC Static Dissipative Coat- ing for Powder Coating Non-Traditional Substrates.” European Coatings Journal, April 2017.

Featured Photo: Source: Dmitry Perov – stock.adobe.com