The previous article titled Remain Bug Free with Antimicrobial Coatings described fundamental aspects of Antimicrobial (AM) coatings as well as AM agents. This article will provide an update on AM coatings technology in the form of paint additives and technology approaches that act to kill microorganisms or minimize their growth on the coated surface.

According to the Grand View Research report, the compound annual growth rate (CAGR) is expected to be 13.1% from 2021 to 2028, with a global market size of 8.1 billion USD in 2020. Major market areas include:

- Medical

- Heating, Airconditioning and ventilation (HVAC)

- Food processing and sanitary facilities

- Mold remediation

Antimicrobial materials can function to kill or combat the growth of bacteria, viruses, fungus and algae on the coating surface. Control of microbes can be achieved through the use of antimicrobial technologies that keep microorganisms from multiplying or growing, providing hygienic surfaces in hospitals and the food industry and preserving the integrity of paint films.

This article will focus on antimicrobial materials and approaches to design AM paint films. Applications where AM agents are used in coatings include the following microbe classifications:

- Fungi

- Mold (form of fungus)

- Bacteria

- Algae

- Virus

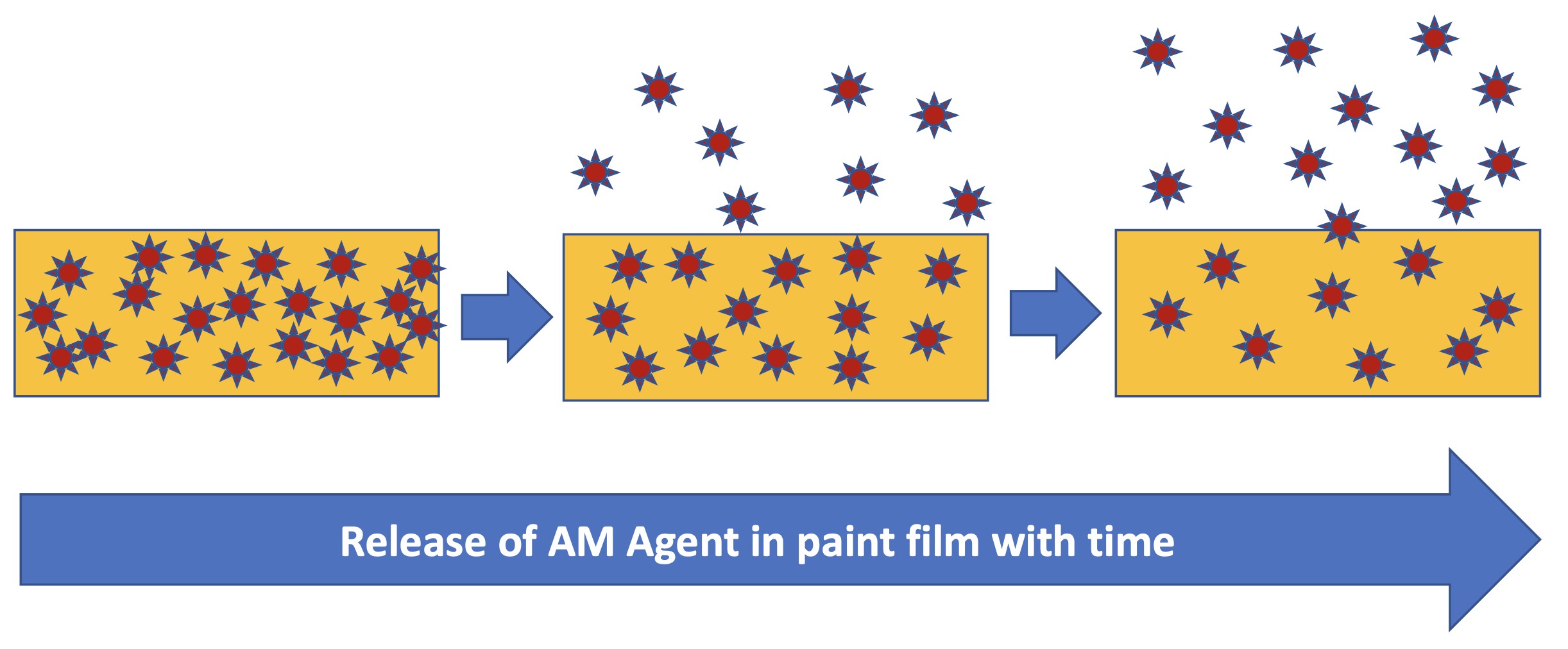

Most biocides used in paints are migratory as they function by releasing the active ingredient to the surface of the coating when exposed to moisture. The longevity of the AM modified paint film depends on the rate of release of the biocide as the concentration of the active ingredient decreases with time.The effectiveness of an AM additive in a paint film is dependent on concentration, resin system, gloss, PVC, coating surface structure and the environment to which it is exposed. The choice of AM agent depends on the desired function in the AM coating system. In addition, before selecting the AM, carefully review the MSD and TDS for safety, environmental acceptability and compatibility prior to incorporation in a paint.

Examples of AM agents

- Mold/Fungi

- IPBC (3-iodo-2-propenyl-butyl carbamate)

- BBIT (N-butyl 1,2 benzisothazolin-3-one)

- Zinc dimethyl thiocarbamate

- 2-n-octyl-4-isothiazoline

- Bacteria

- Tetrahydro-3,5-dimethyl-2h-1,3,5-thiadiazine-2-thione

- Zinc oxide/1,2-benzuisothiazol-3-(2H)-one

- Zinc Pyrithione

- Silver-zinc Zeolite

- Carbon-based materials (graphene, carbon nanotubes etc.)

- Algae – many of the AM agents that are effective for Mold and Fungi are also effective to control Algae growth

- Virus

- Silver zeolite, silver compounds and silver nanoparticles

- Copper and copper alloys

- Carbon-based materials (graphene, carbon nanotubes etc.)

How do AM Agents Function in Coatings?

- Metal and Metal Compounds and Metal Nanoparticles

The use of metals such as silver, copper (and many copper alloys ) and zinc in various forms in paints can be effective antimicrobial additives. There are several mechanisms by which silver acts as an antimicrobial. One such example is that silver ions react with the thiol group in enzymes leading to cell death. The mechanisms through which copper acts to destroy cells include the generation of hydrogen peroxide in the cells or excess copper can also bind with proteins resulting in the breakdown of the protein into nonfunctional sections. Zinc pyrithione/2-propynyl butylcarbamate acts both as a preservative and as a fungicide. The EPA oversees the regulation of antimicrobial agents and materials and determined that copper alloys kill more than 99.9% of disease-causing bacteria within just two hours when cleaned regularly. Copper and copper alloys are unique classes of solid materials as no other solid touch surfaces have permission in the U.S. to make human health claims. Accordingly, the EPA has granted antimicrobial registration status to 355 different copper alloy compositions. Metal nanoparticles, including PVP and polysaccharide-coated silver nanoparticles, MES-coated silver and gold, have also demonstrated promise as antiviral agents. Copper nanoparticles have demonstrated antimicrobiological activity with Ecoli, fungus and bacteria.

- Quaternary Ammonium Compounds

Some examples include dimethyloctadecyl (3-trimethoxysilyl propyl) ammonium chloride, alkyldimethylbenzylammonium chloride and didecyldimethylammonium chloride. Some silanes form a needle-like surface structure by the bonding of 3-(trihydroxysilyl) propyldimethyloctadecyl ammonium chloride to the surface to destroy microbes by rupturing their outer membrane as they come in contact with surface spikes.

- Carbon-Based Materials (CBMs)

Graphene materials (GM) such as graphene oxide, reduced Graphene Oxide (rGO) and Carbon nanostructures (CNSs) such as fullerene and carbon nanotubes (CNTs). There is not total agreement on how these materials function as AM agents (bacteria); however, the unique physicochemical characteristics such as particle size, morphology and surface structure properties of CBMs provide nanoknives, oxidative stress and wrapping/trapping of microbes.

- AM Smart Hydrogels

Hydrogels are comprised of 3D networks of crosslinked hydrophilic polymers that are responsive to changes in environmental stimuli such as pH and temperature that result in the destruction of microbes.

- Cationic Polymers

Cationic polymers are defined as polymers with an electropositive charge on the polymer or AM backbone. They have efficacy in use in AM coatings and are unique in the fact that they have the ability to kill microbes on contact. As opposed to conventional bioactive materials, appropriate cationic polymers and functionalized molecules can be effective without the release of AM chemicals. Such chemicals are currently used in biomedical applications and include ammonium, phosphonium, sulfonium, pyridinium salts and guanidines. Many of these materials with cationic salt functionality have broad antibacterial activity.

- Self-Cleaning Surfaces

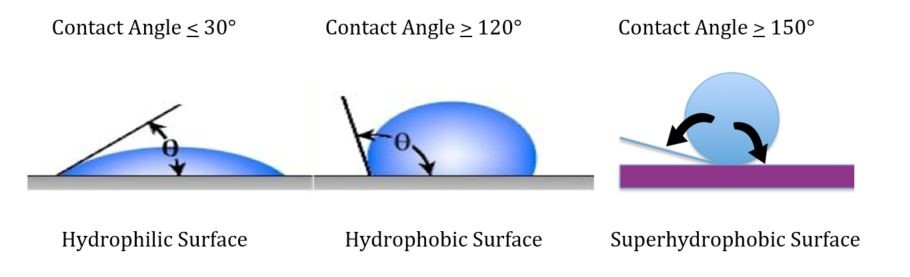

There are three categories of self-cleaning surfaces, superhydrophobic, photocatalytic and superhydrophilic. Superhydrophobic surfaces (contact angle > 150 degrees are water-shedding and thus repel dirt. As many superhydrophobic coatings have a low water-roll-off angle (ROA), this characteristic also provides self-cleaning properties. The surface structure of SH coatings is characterized by a needle-like micro-structure coupled with components that provide a low surface tension. Such surface structures also have efficacy in reducing the ability of microbes to adhere to the surface, thus imparting antimicrobial activity. Photocatalytic surfaces degrade surface deposits when exposed to light. Superhydrophilic coating surfaces (contact angle < 10 degrees) enable dirt and water to easily slide off the surface.

Final thoughts

The future of AM coatings technology will include a combination of technologies that will maximize their effectiveness and longevity. This may include the incorporation of AM agents in Self-cleaning coatings, the addition of slow-release AM nanomaterials and that are absorbed or adsorbed on high surface area particles. Smart AM materials that respond to environmental stimuli such as fluctuations in pH and/or temperature as well as have a surface structure that can rupture the offending cell membrane.