Paint film defects can appear during or immediately after application or become more apparent after the coating is cured. While there is no standard convention for the nomenclature of film defects, this article will separate film defects into the two categories mentioned above.

Copyright: paylessimages / 123RF Stock Photo

Paint film defect causes

The largest number of paint defects is from dirt particles1embedded in the paint. Most other paint defects are the results of:

- lack of cleanliness

- surface preparation

- application error

- attention to detail

Surface tension

Many coating defects are related to surface tension issues. Surface tension is the elastic tendency of liquids that make them acquire the least surface area possible. This occurs when the forces at the interface of a liquid differ from those within the liquid, attributed to uneven force distribution of molecules at the surface. A common unit of surface tension is dynes/cm2 (force/unit area).

For example, applying a coating with a higher surface tension than the substrate may cause dewetting, crawling, pinholing, holidays and telegraphing.

Likewise, the difference in surface tension at the paint surface can result in cratering or fisheyes.

Table 1: Surface tension of paint Solvents

| Solvent | Surface Tension Dynes/cm |

| Water | 72.8 |

| Toluene | 28.4 |

| Isopropanol | 23.0 |

| n-Butanol | 24.8 |

| Acetone | 25.2 |

| Methyl propyl ketone | 26.6 |

| Methyl amyl ketone | 26.1 |

| PM acetate | 28.5 |

Table 2: Liquid surface tension of Polymers used to reduce surface defects

| Polymer | mj/m2 |

| Poly(dimethylsiloxane) | 22.6 |

| Poly nButyl Acrylate | 33.7 |

| Poly nButyl Methacrylate | 31.2 |

Highly polar molecules (e.g. water) have a higher surface tension than less polar materials (see Tables 1 and 2). Surface defects can often be reduced or eliminated by using small amounts of additives with low surface tension such as polydimethyl siloxanes (DMS), poly butyl acrylate or poly 2-ethyl hexyl acrylate. These additives tend to migrate to the surface to help flow and leveling.

Table 3: Defects that can occur during or soon after application

| Defect | Appearance | Causes | Remedy |

| Crawling | Uneven film thickness, dewetting | High surface tension paints applied to a substrate with lower surface tension. For example, paint on steel with oil on the surface |

|

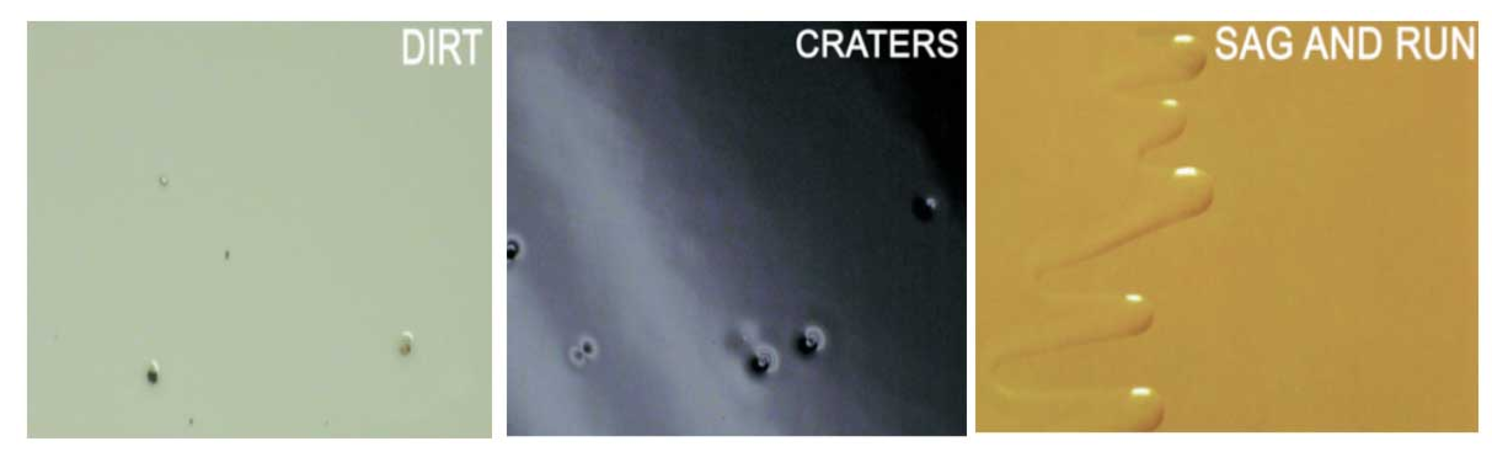

| Craters/fish eyes | Small round depressions in the surface of the coating | Small particles of a low surface tension contaminant (e.g. oil, grease, silicone oil, wax) on the substrate or that embeds in the coating |

|

| Crazing, cracking | Small cracks formed in the coating. This can occur on recoat or if coating is applied to solvent sensitive plastics | Application of coatings on plastics where the paint contains strong solvent that solvates the underlying coating layer or plastic substrate |

|

| Dirt, contamination | Small raised imperfections in the surface of the coating |

|

|

| Loss of gloss, blush | Areas of low gloss or a white haze | Humidity condenses on the wet paint due to the cooling effect of solvent evaporation when the substrate temperature is below the dew point. Causes:

|

|

| Mottling | Uneven appearance of metallic paints |

|

|

| Poor hiding | · Uneven paint coverage |

|

|

| Runs and sags | Drips and sags |

|

|

| Skips/holidays | Incomplete paint coverage |

|

|

| Striping, banding | Stripes of uneven paint appearance (e.g. differing color) | Uneven paint application |

|

| Telegraphing | Highlighting of the surface of the coated substrate through the coating. Such defects as fingerprints, sand scratches and water spots on the substrate become visible on the coating surface | Coating with high surface tension applied to a substrate with lower surface tension. e.g. Fingerprints or silicone oil on a substrate surface. |

|

| Wrinkling, lifting, aligatoring | Upon applying an overcoat, the existing paint film shrivels, wrinkles or swells; may also occur during drying. | Solvents in the new paint swell the underlying paint finish. |

|

Table 4: Defects that are more apparent after cure

| Defect | Appearance | Causes | Remedy |

| Air entrapment | Similar to solvent popping or bubbles | Paint pump sucking air when paint level is low. In two component urethanes, moisture present reacts with isocyanate to cause CO2 generation. |

|

| Barnard Cells | Hexagonal pattern in the surface of a cured paint film. | Convection pattern from pigment segregation as a result of surface tension differentials | Adjust formulation to overcome flooding and differential surface tension at surface |

| Blisters | Bubbles near the surface of a film during oven cure that do not break through the surface. | Viscosity of the surface of the film increases to a high level, trapping the volatile solvent at a lower level. |

|

| Orange peel | Rough surface that resembles the surface profile of an orange | Paint applied at high viscosity or under conditions deleterious to proper flow and leveling. |

|

| Solvent pop | Broken bubbles at the surface of a film that do not flow out during oven cure | Viscosity of the surface of the film increases to a high level, trapping the volatile solvent at a lower level. The bubbles break the surface when the solvent volatilizes. |

|

Search Prospector for formulating remedies to overcome paint film defects:

| Defect | Remedy material |

| Crawling and substrate wetting |

|

| Craters and fish eyes |

|

| Runs and sags |

|

| Telegraphing |

|

| Air entrapment |

|

| Solvent pop, blisters | For melamine cure systems:

|

To read more, please click here to head over to UL Prospector.

__________

Ron Lewarchik, Author of article & President of Chemical Dynamics

As a contributing writer, Ron pens articles on topics relevant to formulators in the coatings industry. He also serves as a consultant for the Prospector materials search engine, advising on issues related to optimization and organization materials within the database.